In the realm of foam mattress manufacturing, the choice of materials and the intricacies of the production processes are pivotal in determining the quality and comfort of the final product. From the selection of viscoelastic foams to the implementation of cutting-edge technologies for layering and bonding, manufacturers are continuously refining their methods. Yet, as regulatory standards evolve and consumer demands for sustainability intensify, manufacturers face the challenge of adapting without compromising performance. This ongoing transformation in material selection and manufacturing techniques not only affects product quality but also raises significant questions about the future of mattress production. How will these shifts impact the industry's commitment to comfort and sustainability?

Memory foam, initially developed by NASA's Ames Research Center in the 1960s, was engineered to alleviate the intense pressure astronauts experienced during the high G-forces of takeoff and reentry. This creation epitomized foam technology's potential in both space innovation and subsequent commercial applications.

Despite NASA's decision not to implement it in space shuttles, the recognition of its broader utility marked a significant phase in material development.

The transition of memory foam from aerospace to commercial markets underscores a strategic pivot in product evolution, with Dynamic Systems first adapting the foam for medical and sports equipment. This adaptation showcases a crucial shift; what was once solely a result of aerospace engineering became a pivotal innovation in consumer products.

Building on its initial aerospace applications, memory foam has evolved into various types tailored to meet diverse consumer needs and preferences.

1. Traditional Memory Foam

Features: Known for its ability to contour closely to the body, traditional memory foam provides a deep, cradling effect. This helps relieve pressure points and supports proper spinal alignment.

Considerations: It may retain heat, which can be uncomfortable for hot sleepers.

2. Gel Memory Foam

Features: Infused with cooling gel beads, this type of memory foam is designed to disperse body heat more efficiently. The gel helps maintain a cooler sleeping surface, ideal for people who tend to sleep hot.

Considerations: Gel memory foam is a good middle-ground for those who want contouring support without excessive heat retention.

3. Plant-Based Memory Foam

Features: Made with a portion of plant-based oils, this eco-friendly alternative reduces the reliance on petroleum-based ingredients. It is often more breathable and has a faster response time, making it cooler and more responsive than traditional memory foam.

Considerations: This foam type appeals to environmentally conscious consumers, though it can be pricier than other options.

4. Copper-Infused Memory Foam

Features: Copper particles in the foam offer antimicrobial and heat-dissipating properties. Copper is naturally cooling and helps keep the mattress surface hygienic by inhibiting the growth of bacteria.

Considerations: Ideal for sleepers who prioritize both cooling and hygiene, copper-infused memory foam is a premium option with additional health benefits.

5. Graphite Memory Foam

Features: Graphite memory foam combines traditional foam with graphite particles that help to draw heat away from the body, maintaining a cooler sleeping environment. Graphite is highly conductive, enhancing cooling without compromising foam durability.

Considerations: For those who want advanced cooling technology, graphite memory foam is an effective option, often found in higher-end mattresses.

6. Open-Cell Memory Foam

Features: This type of memory foam has an open-cell structure that allows for better airflow, helping heat escape more easily. The open cells provide a lighter, more breathable foam with a slightly quicker response time.

Considerations: Open-cell memory foam is a great option for sleepers seeking a balance between breathability and support without the added cost of gel or copper infusions.

Each variation of memory foam provides distinct benefits, allowing consumers to choose based on personal health needs, environmental considerations, and specific comfort preferences, thereby offering comprehensive customization options.

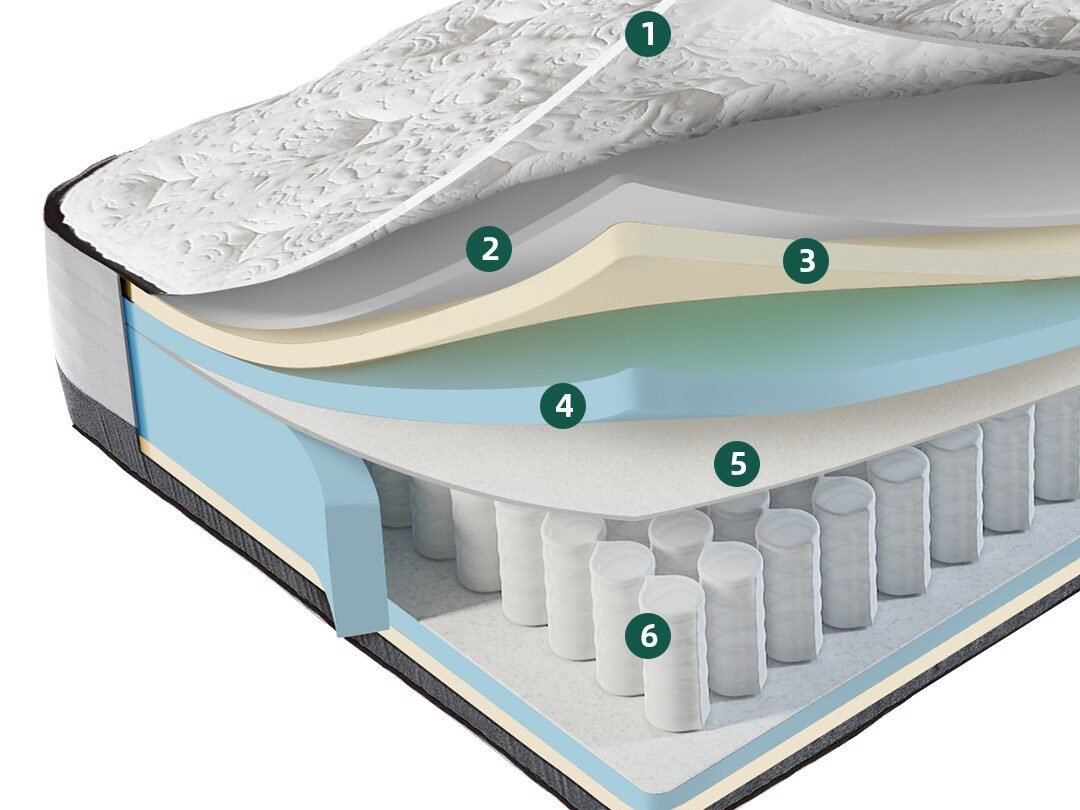

The quality of a foam mattress is rooted in the materials used in its construction. Each component, from the foam layers to the fabrics and stitching, plays a specific role in providing comfort, durability, and support. Here’s a table layout to illustrate the foam mattress construction, showing each layer and its corresponding material and purpose:

| Layer | Material | Purpose |

|---|---|---|

| Outer Cover | Cotton Fabric | Provides a breathable, moisture-wicking surface. |

| Comfort Layer | Quilt Fabric | Adds plushness and aesthetic appeal to the mattress. |

| Contour Layer | Memory Foam | Contours to the body, offering pressure relief and support. |

| Support Layer | Relax Foam (PU Foam) | Creates a stable, high-density base to support upper layers. |

| Base Layer | High-Density Foam | Provides foundational stability for overall mattress durability. |

By choosing eco-friendly raw materials, manufacturers can appeal to environmentally conscious consumers, aligning with modern values and regulatory demands for sustainability in production.

While all memory foams serve the basic function of cushioning, not all foams are created equal in terms of quality, performance, and durability.

A critical factor in distinguishing between different memory foams is the density comparison. Higher density foams generally offer better support and longer-lasting comfort, but they can also lead to increased heat retention. This is a significant concern for users who prefer a cooler sleeping surface, as denser memory foam tends to absorb and retain body heat.

Durability factors are another crucial consideration. Foams with higher density not only resist sagging and body impressions but also tend to maintain their supportive characteristics over a longer period. However, this increased durability often comes with a higher price tag, leading to significant price variations across different memory foam products.

Moreover, consumers should be aware of off-gassing concerns. Memory foams can emit volatile organic compounds (VOCs) due to the chemicals used in their production. While this effect tends to diminish over time, it can be a significant factor for those sensitive to smells or with allergies.

Memory foam mattresses consist of a base layer of regular polyurethane topped with memory foam and potentially additional padding layers.

| Layer | Material | Description and Purpose |

|---|---|---|

| Top Layer | Softer Memory Foam (60 kg) | Provides the initial soft feel and comfort layer. Conforms to body shape for pressure relief and cushioning. |

| Middle Layer(s) | Firmer Memory Foam (70 kg) | Adds deeper contouring support while maintaining the softness needed for comfort. |

| Support Layer | Reflex Foam (High-Density) | Provides firm support, preventing excessive sinking into the mattress and stabilizing the memory foam layers above. |

| Adhesive Layers | Chemical Adhesive | Binds each foam layer together securely, creating a one-sided mattress that maintains integrity over time. |

| Base Layer (Optional) | Additional High-Density Foam | In some designs, an additional dense layer is added at the base to enhance durability and maintain the mattress’s structural support. |

This table represents the layer-by-layer construction, showing the progression from soft to firm, ensuring comfort and support are balanced.

Understanding the construction of memory foam mattresses leads us to explore how the memory foam itself is produced. The process begins with chemical reactions involving isocyanates and polyols that form the basic building blocks of memory foam. During the mixing, reacting agents are combined in a controlled environment to ensure consistency and quality.

Once mixed, the substance undergoes foam expansion. This is achieved by incorporating gas or blowing agents, which help the mixture froth up and expand within a mold. This step is crucial as it determines the density and, consequently, the firmness of the final foam product.

After the foam has reached its desired expansion, it transitions into the foam curing phase. Here, the foam is allowed to stabilize and harden in a controlled temperature setting. This can last a few hours to several days, depending on the specifications required for the foam.

Post-curing, the foam undergoes stringent quality control checks. It is washed, dried, and meticulously inspected to meet industry standards. The final step in the production process is foam cutting, where the cured foam is sliced into precise sizes and shapes for mattress construction.

Here is a brief overview of the memory foam production process:

| Step | Description |

|---|---|

| Chemical Reactions | Mixing of isocyanates and polyols |

| Foam Expansion | Addition of blowing agents to increase volume |

| Foam Curing | Stabilization and hardening of the foam |

| Quality Control | Inspection, washing, and drying of foam |

| Foam Cutting | Precise slicing of foam for mattress use |

The manufacturing process of foam mattresses involves several key steps, starting with the acquisition or production of a flexible foam block. This foundational material is pivotal in the creation of high-quality foam mattresses. Ensuring consistency and quality in the foam is critical for the following phases of manufacturing.

The manufacturing journey starts with feeding material inspection. This initial step ensures that raw materials are carefully selected and measured in precise proportions. The quality of these materials is essential to the efficiency of production and the final mattress quality.

This stage includes two key processes that operate in parallel:

This step involves:

Foam and cotton layers are now glued onto the spring unit. The previously prepared tucked fabric is then attached to the top of the mattress structure, creating a sturdy and layered mattress body.

With the help of a tape edge sewing machine, the edges of the mattress are sealed. This step involves sewing the top and bottom layers together, enhancing the mattress's durability and preventing any shifting of the internal layers.

The final stage includes two critical tasks:

Throughout these stages, manufacturing efficiency is emphasized to optimize resources and minimize waste, ensuring a product that aligns with consumer expectations and environmental responsibilities.

The process of manufacturing memory foam mattresses involves several key steps that create their unique structure and comfort.

Memory foam production begins by combining polyols (alcohols from petroleum or plant oils), isocyanates, and catalysts (reacting agents) to initiate a controlled chemical reaction, which forms the base for memory foam’s signature density and viscosity.

The ingredients are then whipped into a frothy mixture, which is poured into molds. The mixture undergoes an exothermic reaction (releasing heat), which creates the cellular, foam-like structure as it expands.

To control the foam’s density and structure, gas or eco-friendly blowing agents are added to the foam mixture, or the foam is vacuum-sealed to create open-cell structures, which impact breathability and softness.

The foam, now referred to as a "bun," is cooled and then reheated to stabilize it, curing over several hours or days to set its structure.

Once cured, the foam may be washed to remove any residual compounds. It is then inspected to ensure quality and consistency before being prepared for cutting.

The foam is cut into mattress-sized sections, forming the memory foam layers ready for assembly.

Each mattress is built with a supportive polyurethane core and layered with memory foam for comfort. Layers are bonded using adhesive and then wrapped in a flame-resistant barrier to meet safety standards. The mattress is finished with a cover for aesthetics and comfort.

This streamlined process highlights the essential steps in creating a memory foam mattress, from mixing the ingredients to the final assembly.

The lifespan of a typical foam mattress hinges on durability, maintenance, and wear factors. Generally, with proper care, these mattresses endure 8-10 years before foam degradation significantly impacts comfort and support.

Yes, foam mattresses can be recycled, promoting waste reduction and sustainability practices. Recycling options vary, focusing on material reusability to minimize environmental impact and enhance the sustainability of manufacturing processes.

The best way to clean a foam mattress involves spot cleaning for stain removal, using baking soda for odor control, vacuuming for allergen prevention, and following regular maintenance tips to prolong mattress life.

Foam mattresses, like a tailor's fabric, adapt to diverse body shapes through various firmness levels and supportive layers, ensuring optimal weight distribution but consider heat retention and durability factors for long-term satisfaction.

Foam mattresses may soften over time, affecting firmness, comfort, and durability. This change, influenced by foam density and aging effects, may not align with all comfort preferences, raising potential durability concerns.

In conclusion, the artistry of foam mattress manufacturing merges state-of-the-art technology with meticulous craftsmanship.

The journey from raw, ethereal clouds of materials to the substantial, comforting embrace of a final product epitomizes a near-magical metamorphosis.

As the industry strides toward sustainability, this evolution not only reflects advancements in material sciences but also underscores a commitment to environmental stewardship.

Thus, each mattress is not merely a product but a testament to innovation and ecological mindfulness.

Shangrou Furniture Co., Ltd., established in 2011, is a leading mattress manufacturer specializing in diverse designs, including pocket springs and foam. With advanced technology and 100% OEM/ODM services, we provide high-quality, innovative mattresses for global brands, ensuring exceptional craftsmanship and long-term partnerships.